Carb Choices

You would have to think that almost anything would be better than a Zenith Stromberg carburetor with water controlled “choking.” This was the remedy that Triumph chose for the Spitfire in order for them to continue sales to the US market. The Zenith Stromberg CV carburetor is a pretty good unit in itself. After all the GT6 and TR6 came with these carburetors in paired sets, and with very few complaints. Years later when the emissions rulings came into effect, the oh so reliable manual chokes would have to be scrapped for a tamper proof system that was beyond the operators control. (I guess some of us were leaving the chokes on longer than they would have liked.) The rules called for an automated enrichment warm up circuit. The choice made by Triumph was a choke that was controlled by coolant temperature. As perfect as this concept seemed, (as it is still being used today in all fuel injection systems,) it was its layout that was so poorly executed. It hardly had a chance being located directly above the blistering hot catalytic converter. This newly fitted warm up circuit would plague these cars to their very end. Upgrading the water choked Strommy to an aftermarket replacement would not only alleviate all the problems it created, but add smoothness and power as well. Don’t get your hopes up too much, giving those Miatas a run for their money will take more than just a carburetor change.

So what are all of the options available for the Spitfire and GT6 anyway? How does one choose what is best for them? What is the best performing system out there, and what can I expect from it? Will I be able to get parts easily if need be? Will I be able to tune it, or will I have to take it to a professional? These are only a few questions one might ask themselves when considering a new induction system. Options? Lets see, there is electronic fuel injection from Electromotive and TWM, single or paired two barrel side draft carburetors by Weber, single two barrel down drafts from Weber, (progressive or non progressive) and new to the scene are Japanese high performance quad and paired carburetor systems from Mikuni, and Keihin (Kay-hin).

We will go through these options one at a time and try to make it a little more understanding, hopefully giving a clearer picture for a more conscience choice.

Electronic Fuel Injection

We will start with the high tech systems of Electronic Fuel Injection (E.F.I.) There are two companies that offer E.F.I., they are Electromotive, and TWM. Electromotive has the most advanced and complex system that will adapt to these cars. It is completely programmable as is the TWM system. It is also found on many high dollar race cars. These systems are capable of unmatched performance under almost any condition. Once installed and programmed the only maintenance left to do are valve adjustments, spark plug and filter replacement. What makes these injection systems different from production vehicles is their programmable versatility via laptop. The system on production vehicles is limited for tamper proofing and emissions reasons. They operate through a small window of variance, limiting its automated adjustment spectrum, which best suits efficiency and emissions control. This is why performance chips have become popular. What these “chips with salsa” do is alter the cars fuel mapping and ignition timing curves. Accuracy will depend on the deciphering of the original chips code, then burning the modified data onto the new chip. If the use of a dynamometer is not incorporated during the development process the chip it will be weak in certain areas creating flat spots in the power band. This is why some performance chips work well and others do not. Even if your chip works to its best potential and you have purchased the upgraded Electronic Control Unit (E.C.U.) to go with, you are still dealing with an inferior system in comparison. This is due to the slower reaction time of which the production system operates. Programming your aftermarket E.F.I. system with a lap top computer will allow you to pin point the perfect state of tune through out the entire rpm range without the use of a dyno. Programmable or not, E.F.I. requires a good steady electrical source, so the original 45 amp alternator on your Triumph should be up-graded to accommodate the demands of these hi tech systems. A drop in a bucket compared to the approximate $3000 price tag attached to these ultimate tools, which will certainly bring out the best of what your engine has to offer. (Laptop not included)

SU Carburetors

Although not mentioned above, they were original equipment installed in pairs on the early Triumphs before switching to the Zenith Stromberg. Make no mistake, these side drafts still hold their own in the vintage performance world. In fact properly sized and tuned, these units can produce nearly as much horse power as the more favorable DCOE side draft series from Weber. The SUs however, do require more maintenance than the Webers. For instance the throttle shafts tend to wear in their bores, resulting in major vacuum leaks at various throttle positions, which will also play havoc with idle control at every stop. While replacing the worn shafts with over sized units will solve this problem, they will begin to repeat this fault with slow progression within a couple of years after the fix. Another problem is with today’s fuels not being so friendly to their rebuild kits. The alcohol in the fuel seems to eat the o-rings and paper gaskets causing seepage. Nonetheless, if you’re into performance with originality and love to tinker, SUs are a good candidate. Even if your engine has not been modified these carburetors will still increase performance providing your replacing the single Zenith Stromberg. Something to consider if you are going to race is, there are sanctioning bodies that will allow a 100-pound weight advantage for cars using SU carburetors over cars using the Weber side drafts. This century mark weight loss program would be the same as a 10 hp increase by itself. Hummm!

Zenith Stromberg Carburetors

The factories choice for the later Triumphs. Very similar to SU in that they too are a constant velocity (CV) or constant depression (CD) type systems. Same meaning, different terminology. These carburetors automatically adjust themselves to the engine’s speed for the smoothest power delivery no matter what your right foot is doing. The air valve, piston, or slide, which ever you prefer, rides atop the vacuumed charge of air that is drawn in though the venturi as the piston strokes downward and the intake valve opens. What happens here is the air valve automatically adjusts the venturies size for the engines current demand. The independently floating air valve reacts to the positioning of the throttle plate, which is operated by the accelerator pedal. As you depress the pedal, the throttle plate reacts instantly while the air valve’s reaction is secondary and a bit lethargic caused by several stipulations. Which are, the weight of the air valve itself, spring tension, the port holes at the base of the air valve, and that it is dampened by the oil that is occasionally required in the top of these carburetors. Speaking of which, we have found a 70/30 mixture of automatic transmission fluid (ATF) and Marvel Mystery oil work best in all weather conditions. Anyway, even though your foot may be to the floor the air valve will only rise with the engines speed. One would really have to try and bog the engine to do so. This clever design constantly controls the air speed velocity for best results. As with SU, these simple yet ingenious carburetors will also compensates for altitude changes. Except for the water temperature controlled choke system the Zenith Stromberg carburetor is very reliable and responds very well to over hauls if needed, providing one does not forget the air bypass circuit. There were never any high performance versions offered by Zenith Stromberg. However, stepping up in size from the 150, to 175 and or mounting additional units (Note: 2 for the 4 cyl. and 3 for the 6 cyl.) is the key to more power if you really like these carburetors. This adaptation should be done with the earlier manual choked units. Triple CD 175 manifold kits are currently available only for the TR6 at this time.

Weber Carburetors

Webers offers several different options for the Spitfire, GT6 and TR6. Actually, carburetor manufacturers only make the carburetors. It is usually an outside company or the auto manufacturer that designs and produces the manifolds and hardware to adapt carburetors of choice for their specific applications. Weber carburetors are very popular in the racing and performance place. These carburetors through history have fed some of the worlds fastest cars prior to fuel injection, and still are a favorite with most vintage racers and sports car builders. Webers are very reliable carburetors, once set up you are pretty much good to go with minimal maintenance. Weber offers both down draft, and side draft versions. The most common replacement fix for the Spitfires water choke Stromberg unit is Weber`s DGV 32/36. This model has two barrels or venturies of unequal-equal size. The smaller of the two venturies (32) is what the car mostly operates through until more power is demanded. At approximately 3/4 throttle the progressive linkage begins to open the second and larger of the two barrels (36). It’s a best of both worlds type setup if you’re looking for a little more punch without sacrificing economy. Weber two barrel down drafts also come in a non-progressive style or DCNF, in which both venturies or barrels operate simultaneously and are of the same size. This system offers more power through out the entire rpm range over the progressive style, and like most Weber carburetors their venturies sizes are interchangeable, so you can replace them with larger venturies if you decide to modify the engine later.

Weber’s top line, the DCOE side draft series, are their ultimate performers. They are perfect for Triumph’s intake port design, which are horizontal, so why not use horizontal or side draft carburetors. This was thought to be the optimum layout for an induction setup at the time, and is why Triumph used it. Remember these cars were designed to out perform all others in their class, and that they did. There differences are, the down draft’s charge is drawn in vertically through the carburetor before having to make an abrupt 90 degree directional change in the manifold before align itself with the intake port. Where as the flow of the side draft goes virtually uninterrupted, a very important feature for improving performance. The advantage of direct path induction is a greater ram effect. This happens when the piston reaches the end of its intake stroke or bottom dead center (BDC) and even as it starts its way back up after bottom dead center (ABDC) the charge is still rushing in through this uninterrupted or straight path, created by the weight and momentum of the charge itself, resulting in a compacting scenario for a bigger bang! Otherwise known as forced induction. Not nearly on the same level as turbo charging or the use of a blower. However, this technique can be amplified through longer intake runners and precise cam timing.

Utilizing side draft induction will also allow manufacturers to design lower frontal body profiles for better wind resistance for front engine cars.

The most powerful, performance oriented, naturally aspirated gasoline engines in production today used side draft induction for many years. This would be the motorcycle industry. The sport or high performance version of a 750 cc bike is literally 1/2 the size of a Spitfire engine and churns out an astounding 120 hp in stock form. This is achieved by designing a cylinder head and induction system with tremendous flow capabilities, the key to making high hp figures. This is how cylinder head technology as comes to 4, and in some cases 5 valves per cylinder. It is all about increasing the flow capacity, or cubic feet of air per minute (cfm), which is how the amount of flow that passes through a cylinder head port is measured. If its horse power you want (who doesn’t!) then choose an induction system (carb, manifold combination) that will net the highest cfm. You will also want to go as large as possible with the venturi sizes without sacrificing drivability.

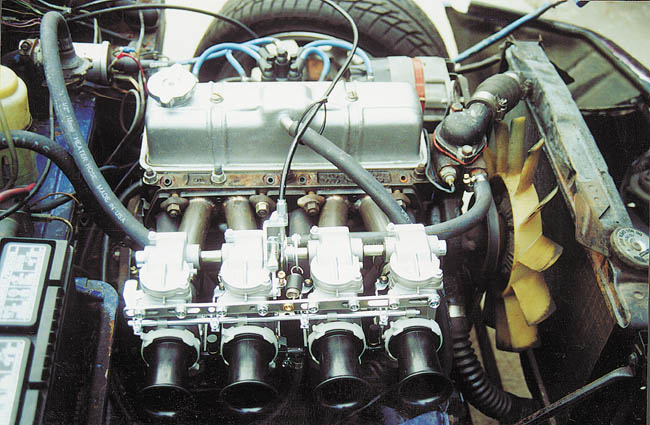

This brings us to the last of our list of options, as well as the latest in carburetor technology. The Mikuni and Keihin high performance motorcycle carburetors. So you ask. Motorcycle carburetors on a car? Why not? A carburetor is a carburetor, and does not care what it is mounted too, nor will it react differently. These motorcycle racing carburetors flow a tremendous amount of cfm over their best competitors (Weber DCOE) matched size. What is also interesting is that these two carburetor manufacturers also make the original equipment carburetors for all production line motorcycles today. Going one step further, these o.e. carburetors design and manufacturing are nearly identical copies to the CV style Zenith Stromberg units with the exception of oil dampening, and of course the water choke. These induction systems from Japan will out perform any other carburetor package out there, in both power and fuel economy. Some of these carburetors advantages are they do not have throttles plates, slow speed venturies, or depression steps to obstruct their flow path. Though operating on the same principal and mechanics as the Stromberg and SU, they are not a CD, or CV system. The accelerator cable operates a rod directly fixed to the air valves, which means you have full control of the air valve via your right foot, making the action direct, not secondary. For instance, driving a Spitfire with this system one must learn to discipline the right foot by rolling into the power as opposed to mashing it to the floor and waiting. These carburetors are more sensitive to input over the Webers due to their accurate fuel metering. The Keihin or Mikuni carburetors do not have multiple venturies in each barrel like the automotive style carburetors, which causes unwanted turbulence in the flow path. Ultimately this hinders maximum ram effect capabilities. Fig. A shows Keihin’s quad setup standing alone. Fig. B shows the near total unobstructed flow path of the Keihin CR Specials. Fig. C shows the set mounted to a Spitfire while throttles are held wide open. The only obstruction in the flow path or venturi is the very thin fuel-metering needle. (Note the absence of the butterflies as well.) The blurred object far behind the jet needle is the intake valve and guide of this un-ported head. Compare the diagrams of the Keihins with the Weber DCOE.

The Mikuni Corporation uses sliding door technology otherwise known as flat slides. This design is a carry over from the Lucas sliding door injection that was successfully used by both Jaguar and Cosworth racing. Flat slide technology makes extremely high manifold vacuum, aiding in fuel atomization while increasing port velocity. Mikuni also incorporates accelerator pumps to enhance throttle response. The Mikunis are generally better suited for extreme street performance or race applications, where as the Keihin carburetors are more user friendly for daily driving, but will still match the Mikuni’s performance at full throttle. Both carburetor systems are very reliable, and easy to tune and maintain. Parts for them are also much less expensive, and fewer than any other automotive style carburetor. With only three jets to deal with, idle, main, and air correction, you can have them perfectly adjusted in an afternoon. For those of you already familiar with Weber’s DCOE know that one could easily spend a week or so trying to get them perfect, only settling for “hell, that’s close enough!” With all do respect the Webers do work very well when jetted to perfection, and have been the standard in the industry for years. However, the flow bench does not lie. Horse power gains over the Webers are a fact. I has been installing these carburetors on Spitfires and other 4 cylinder engines such as Alfa Romeo since 1984. I believe the reason these carburetors are not more widely used in the automotive field is that the two fields have a huge barrier between them. The high performance car industry generally sticks to what was developed for their particular application, and the opposite is true as well. Most people do not think about cross adapting technologies, or are familiar with all the different products available.