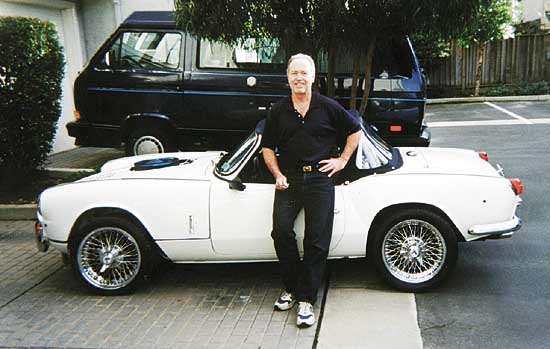

Dave West’s Chevy 327 V-8

BEGINNING OF THE PROJECT, WHY, WHEN

Why do mountain climbers climb mountains? Answer: Because they are there! Why do some auto enthusiasts modify their cars? Same answer! Some other answers include:

“I want more power!”

“I want to improve the handling!”

“I just want to own a very unique car – a one of a kind!”

You can probably add your own answers to the list. But, the bottom line is that, whatever the reasons, you plan the project then build it. As an example, let us pay a visit to a radically modified Spitfire, The Beast.

The Beast, was conceived and constructed by Dave West of Campbell, California. The idea for the project came to Dave one afternoon as he worked on his then current project – an Austin Healey Bug-Eyed Sprite – into which he had shoehorned a Ford flathead V-8. The Sprite was a problem child from the beginning and required a lot of upkeep and repair. As Dave labored to solve a tricky problem on the Sprite, a friend came by for a visit driving a 1964 Spitfire (stock) and Dave vowed, due to the amount of room under the hood, that he would build a better modified based on a Spitfire.

The building of The Beast has been an ongoing process since 1970. In 1969, Dave purchased a Spitfire, which was driven for a year in its stock configuration. Many lunch hours were logged in American and British auto wrecking yards. This time was spent in recording the measurements of several types of candidate V-8s (Chevy, Ford, Buick, & Mopar) and the empty bodies of Spitfires. The time spent in planning made the project straight forward. Not easy, but there were very few surprises.

To start the project, a Spitfire frame was purchased and re-engineered to support the engine and take the increased horsepower and torque. When the frame was complete the engine, differential, rear suspension, transmission, and driveshaft were installed. Then came the suspension modifications. Finally, the brake lines.

Soon it was a complete a rolling chassis and it was time to take the body off of the stock Spitfire and mount it on the new chassis. With the study and planning that were accomplished on the project, the firewall and other body modifications required were completed and the body fell right into place. Now it was just a matter of completing the wiring and several other systems completed.

The Beast was initially on the road in 1971 powered by a stock Chevy 327 V-8, a Muncie 4 speed transmission, and a 1963 Corvette independent suspension. From that point on the car has undergone a long list of changes and improvements to its present configuration. Today, The Beast, is powered by a blueprinted 350 cid Chevy V-8 putting out 350 horsepower and 380 foot-pounds of torque. The Muncie 4-speed transmission has been replaced by a Tremec 5-speed with a 5th gear overdrive ration of .63. The differential gearing was lowered from a gear ration of 3.36:1 to 3.08:1 for better freeway cruising. This ratio, along with the overdrive ratio, provides a great cruising experience on the freeway. With the torque and horsepower of the 350 cid engine, there is no problem moving the 2225 pound car.

The ride of The Beast is much better than you would suspect with the amount of mass represented by the cast iron V-8. The extra weight of the Corvette rear suspension and third member along with the extra weight of the frame modifications helps to balance out the engine and transmission weight. The center of gravity of the car actually moved back about a foot and a few inches lower to the ground with all of the new mass. The car was set on four independent scales that recorded the weight supported by each wheel. It is roughly 56% of the weight in the front and 44% in the rear. With a driver and a passenger in the car, the weight distribution is about 54% front and 46% rear. To enhance the cornering capability of the car, it is taken to a shop that “tunes” the suspension to encourage cornering. All in all, it handles quite well.

FRAME MODIFICATIONS

The frame was fully re-engineered to accept the Corvette rear suspension and to survive the torque and power of the engine. Dave fabricated all of the frame parts and had a company that built off-road “Baha Bugs” TIG weld the assembly. The front engine mounts were placed on the suspension pedestals to provide direct support from the suspension. The transmission mount is within a couple of inches where the old Spitfire transmission was mounted.

The rear fourth of the original frame was redesigned to allow mounting of the Corvette differential. 2 inch x 2 inch box steel rails were run the length of the frame to provide resistance to twist and frame flexing. When you jump on the accelerator and open all barrels, the car moves perfectly straight ahead, there is no sideward movement due to frame flex.

To further stiffen the car and provide for safety, a four-point rollbar was manufactured and installed and welded directly to the frame by Magnum Force Race Car Fabricators, in Campbell California,

In order to fit the Tremec transmission into the car, the original portion of the Spitfire frame (where the frame is the narrowest) had to be modified and strengthened. Magnum Force Race Car Fabricators performed the mods.

UNDER THE BONNET

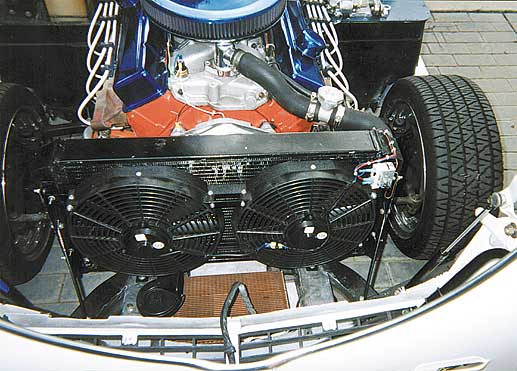

The engine components were balanced and blueprinted. It has a Competition Cams 268 camshaft and roller tip rockers. The engine is rated at 350 hp and 380 foot-lb.’s torque. The intake manifold is a Weiand X-elerator and a Holley 650 double-pumper sits on top of it.

The ignition system is based on a Mallory Unilite Distributor which uses an infrared sensor instead of points. The distributor is joined by a Mallory Hi-Fire Ignition to provide increased fire-power. A 78 amp Delco Alternator replaces the original Lucas electrical system.

The Beast’s cooling system starts with a radiator designed to fit into the confines of the engine compartment: The core is 26 inches by 14 inches and consists of 4 rows of tubes separated by 3/8 inches. A street version of the Moroso electric water pump has replaced the stock belt driven water pump.

Due to the cramped conditions at the rear of the engine, the original General Motors rams-horn exhaust manifolds were retained. A new pair of manifolds are currently being ceramic coated to enhance the view under the hood. In order to run the exhaust to the rear of the car, Mussman Automotive of Campbell, CA had their artist of exhaust systems perform his pipe bending magic and put the pipes up out of sight. They ended the pipes at a pair of turbo mufflers that provide good extraction and great conservative sound.

A planned modification to the engine involves the installation of a set of Twisted Wedge aluminum heads. This will provide three benefits. The first of which is 60 to 70 fewer pounds in the front of the car, the second is that it will provide hardened valve seats to compensate for unleaded gasoline, and finally, the heads will provide approximately 40 horsepower more and boost the torque close to 400 foot-lb.’s.

TRANSMISSION, CLUTCH, & HYDRAULIC SYSTEM

The present transmission is the Tremec 3550 5 speed. The Tremec is one of the few transmissions that can withstand the torque and horsepower put out by The Beast’s engine. The Tremec, originally a replacement for a Mustang transmission, was modified to fit into a General Motors application without having to use adapters. The modified was supplied by Forte’s Parts Connection of Waltham, MA. A “5.0” shift kit was used instead of the stock Tremec shifter to provide for a shorter and very accurate throw.

The hydraulics consist of a Tilton clutch and brake assembly, including pedals, with a three master cylinder design which provides for the proportioning of the braking power between the back front and rear brakes. The slave cylinder-mechanical linkage and throw-out bearing was replaced by the McLeod hydraulic throw-out bearing; a beautiful setup. Originally, with the standard clutch fork and external slave cylinder, the drivers foot room was narrowed by 3 inches. With the hydraulic throw-out bearing assembly mounted to the front of the transmission in place of the bearing retainer, the driver’ foot room was reclaimed.

A very nice outcome of this transmission selection was that the shifter was positioned within 1 inch of the position of the Muncie’s shift linkage. The Tremec is a much larger transmission and the possibility of the shifter being too far back was an initial concern.

REAR SUSPENSION MODIFICATIONS

The 1963 Corvette rear suspension has been the recipient of several transformations which include a 1967 third member that now has 3.08:1 gearing, shortened 3″ diameter half shafts, Vette Brake custom strut rods and trailing arms that were designed to provide the room for the use of 40, 45, or 50 series radials. The 11 inch drum brakes were retained for stopping power.

With the track of the rear suspension narrowed about a foot from the stock Corvette’s track. The transverse leaf spring had to be narrowed accordingly. Then, through experimentation, the right combination of leaves from the Corvette full leaf spring had to be selected to provide the best ride and acceleration response. Consideration was given to have Vette Brakes, of Florida, manufacture a fiberglass spring like those used in the newer Corvettes, but the cost was prohibitive.

FRONT SUSPENSION MODIFICATIONS

The front suspension was modified for strength by boxing in the “A”-arm members and welding a 1/8 inch plate to the underside of the “A”-arm. The upper and lower “A”-arms were modified to accept Chevrolet ball joints. 1967 Chevelle spindles with 9.5″ drum brakes were bolted on and the steering arms modified to match up with the Spitfire rack and pinion steering. The front Koni coil-over shocks were modified by Truechoice Motorsport of Hilliard, Ohio by providing adjustable lower spring seats to dial in the correct ride height and geometry.

Maybe, a future project will be to replace the drum brakes with disks. But, the stopping power of the present system is more than sufficient. The conversion to disks would not add much to this project except for more bragging rights.

INTERIOR AND SEATS

An interior kit, consisting of carpeting, and door panels was purchased from The Roadster Factory of Armagh, PA. The door and rear interior panels were installed at home and modified to allow the 4-point rollbar to reach the frame of the car. Prior to installing the flat portions of the carpeting, Miata tan leather seats were purchased and mounting adapters manufactured for their installation.

The floor pan of the Spitfire was wire brushed to clean out many years of accumulated dirt and grime and some superficial rust. Then the metal was treated with Jasco Metal Etch to stop any future rust and to preserve the metal. Sound deadening material was then laid down throughout the car and in the doors to give the Spitfire that luxury car quiet interior. The carpeting was installed with a 1/2 inch padding and the Miata seats were installed.

A professional interior shop was retained to install those areas of carpeting that required stretching and gluing to curved surfaces. Many thanks to El Gato Auto Interiors in Los Gatos, CA. The owner covered the entire transmission tunnel with a single piece of carpeting – a most awesome job.

To “top off” the interior, a blue fabric convertible top was special ordered. The removable frame for the top was sand blasted and powder coated. The blue top adds a bit more of sexiness to the car and matched the color scheme selected for The Beast (Triumph blue interior and accessories, a bright white paint job with chrome trim.).

The final interior project is now underway; it the construction of a new dashboard with a full complement of VDO gauges. Triumphs Only of San Jose, CA extracted a dashboard frame from a mid seventies Spitfire to replace the small dashboard frame that was stock in the 1964 Spitfire. This will allow the installation of a full width dashboard. This project requires the rewiring of the car from the dash to the front lights. Universal wiring harness kits with rocker switches and fuse block have been purchased and are awaiting their incorporation into the project. A beautiful piece of teak veneer wood has been purchased to provide a face for the dash.

Many body parts are not available anymore and transplants are required. In to eliminate rattles and keep the doors shut, door latches from a 1985 Oldsmobile were transplanted and reconnected to the original door opening mechanisms.

WHEELS & TIRES

Now for the final touch, a set of Zenith 16 x 7 lip laced series I chrome R/R laced wire wheels. Mounted on the front wheels are a pair of Euro T/A 205/40 R16s and on the rear wheels are a pair of Euro T/A 225/45 R16s. The addition of the wheels and the blue top added a high level of sexiness to this modified sports car. The Zenith wheels are held in place by knock-off adopters and three eared knock-offs. With purchase of the wheels you are given a lead mallet and officially inducted into the “knock-off” society.

BASIC DRIVABILTIY (FUN)

Driving The Beast is the fun part. It is a highly dependable car and it has been used for vacations, camping trips, trips to Reno, and many other experiences. The feel of the car on the freeway is very solid. Of course, the ride is a little hard with the spring rates necessary to support the added weight of the engine, rear suspension, transmission, and frame modifications. Entering and exiting the freeway are very fun. With the suspension tuning provided by Wax and Wheels of Campbell, CA. The Beast is glued to the curving offramps near my home.

It is always fun to come down a curvy mountain road in a stock sports car, but with The Beast’s power and good handling, going up the mountain roads are equally as fun. On trips over the Sierras, it performs in the high altitudes almost as well as it does at lower altitudes.

There are many stories of the impromptu races that it has engaged in as well as getting to know it and the awesome acceleration experienced under open throttle. The Beast has been in local hotrod and British car shows for 20 years. Much of the work on the car is now dedicated to making it a polished show car.

CURRENT STATUS as of 1/9/01

The Chevy 327cc V-8 has been replaced with a bored and stroked Chevy 350 cid; the final displacement is 383 cubic inches. The new engine was built by Beck’s Racing Engines of Phoenix Arizona. With iron heads it was dyno’d at 432 hp and 478 ft-lbs of torque. The heads were upgraded to Airflow Research aluminum heads that provide an extra 60 to 80 hp over stock Corvette engines. I would say that conservatively, the new engine will have over 450 hp and 500 ft-lbs of torque.