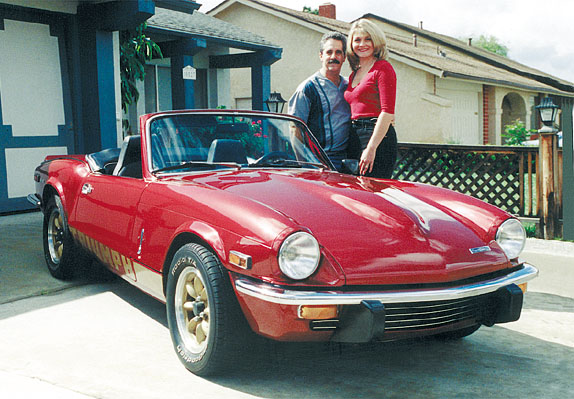

Barry Schwartz’s Ford V6

I originally purchased this car, a 1972 Signal red Spitfire, in 1973 with just over 5000 miles on the odometer. After several breakdowns and just general lack of horsepower, remember the 72 was rated a whopping 48 BHP, I’d just had enough. I was in the local wrecking yard and saw a 2.6 liter Ford Capri and thought, I bet I could stuff that in my Spitfire. That was some 22 years and many iterations ago, and this is the car in it’s current, ever evolving state.

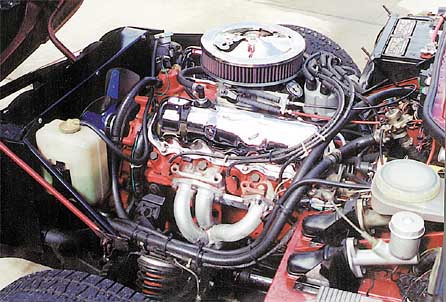

The current engine, a 1974 Ford 2.8 liter V6, which I entirely rebuilt and had balanced, is equipped with a mild street cam (Comp cams) and tube headers which were required in order for the engine to fit. I had to modify the oil pan for frame clearance, which consisted of notching the front of the pan (for the steering rack) and angle notching the right side of the pan (for clearing the suspension mounting assembly). You must use the Capri rear sump pan and oil pump assembly as the regular Mustang/Pinto unit has the deep end of the sump forward which would interfere with the front frame cross member and steering rack. This EuroFord V6 was derived from a V4 with a balance shaft mounted in the right side of the block. When mounting the engine crankshaft centrally in the frame, the engine will appear to be offset to the right. This is the extra material left over from the V4 balance shaft casting, the same basic casting with two extra cylinders added to make it a V6. That’s the reason that the oil pan needs that angle notch on the side for clearance. Stock mounting locations were used on the frame but, naturally, mounting the engine required new mounting brackets, which I fabricated from mild steel and welded together. One of these days I’m going to mill a set from solid aluminum billet, just for appearance’s sake. Stock type GT6/TR6 engine mounts were used. Cooling is handled through a large, custom made, four core, crossflow radiator with dual thermostatically controlled electric pusher fans. The intake system is basically a stock 1977 manifold that uses the Ford 2 bbl Motocraft carburetor mounting, with a couple of slight modifications. I milled approximately 1/2 inch off the carb. mounting flange and made a two piece adapter to mount a Holley throttle body fuel injection unit, normally made to fit an 89 GM S10 truck. I also used the same electronic control unit and sensors, minus the electronic spark control, from that same model truck to supply the engine fueling requirements via electronic fuel injection. With a couple slight program changes to the ECU it runs pretty good, but I have purchased a Haltech ECU to replace the GM unit, and that is FULLY programmable. I plan on getting this set up and running in the near future, and this should really enable me to fine-tune the setup for max performance as well as economy. The fuel tank was modified with a return line and the 20 psig fuel pump sits right below it, mounted on the area that houses the rear spring, and is mostly concealed by the usual fiber trunk board. The ignition is a stock Ford Dura spark ignition system and has proven very reliable.

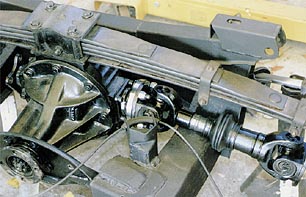

The transmission is now a Borg/Warner world class T5 with cobra ratios and required a few modifications as well. The aluminum 74 V6 Mustang bellhousing needed a little re-working which consisted of machining out the area where the starter motor mounts. Then a new piece was cut from billet aluminum, shaped for the smaller 2600 CAPRI starter (smaller than the stock MUSTANG for frame clearance), welded in place, and re-drilled/tapped for the starter mounting holes (it sounds worse than it actually was). I also moved the throwout bearing actuating arm from the left to the right side of the bellhousing (again for clearance). The stock Mustang uses a cable operated clutch and I wanted to keep it hydraulic. I used a Mazda (truck) clutch slave cylinder mounted on a fabricated bracket to the right side of the transmission. This transmission required a slight trimming of the frame at the flanges and a slight dimple to clear, but nothing major. I also used an allen bolt for one of the lower fasteners on the rear transmission extension for additional frame clearance. Since I had to trim the floorboards slightly (similar to when one adds an overdrive, but a little longer) because of the new length of this transmission, I had to make a new tunnel as the original style would no longer fit. That I fabricated out of aluminum. This transmission is quite a bit larger than the Spitfire unit. Unfortunately, this transmission also required making a new rear transmission u-joint yoke to match the rather smallish u-joints TRIUMPH used on their drive shafts. I used an axle yoke, minus the axle shaft itself (which is pinned and splined together in the usual Spitfire axle configuration), machined that to fit the sliding splined shaft portion from the T5 tranny, then welded them together. In twenty some years of using this drive shaft/yoke combination, I’ve never had a failure of the custom part or u-joints, which have been replaced only once since I did this installation. Mounting of the rear of the transmission was handled by fabricating a new cross member, which bolts in just slightly aft of the original Spitfire transmission mounting locations. Shortening the drive shaft was also required because the new setup is quite a bit longer than even a Spitfire with overdrive.

I also decided to adapt the all-independent GT6+ rear suspension to replace the stock swing spring setup. The modifications required were to make and weld new mounting brackets to the frame for the lower wishbones (at the time I did this, these weren’t available, but now you can buy them). Also, I needed to fabricate and weld the upper shock mounting brackets (you can buy these now as well) into the inner wheel well arches. As luck would have it, I had a GT6+ to use as a guide for fitting and location. 1/4″ spacers were required at the rear for the tires (wider than stock) to clear the shocks at the upper wheel locations. I found that with so much torque available, I was ripping apart rubber doughnuts within months of replacing them, so I needed to do something to strengthen that area of the drive train. I replaced the Rotoflex joints and axles with TR6 sliding axle shafts by re-manufacturing the hubs and differential inner axle mounting flanges to accept larger TR6 U-joints. I also installed a Quaife torque-sensing carrier utilizing a 3:63 gear set. The rear transverse spring was left as a stock Spitfire swing spring. Cruising on the freeway at 70 yields about 2700 relaxed engine RPMs.

Front suspension modifications consisted of using GT6 uprights, rotors and calipers and replacing the Spitfire springs with stock Triumph Herald units. These springs have just a tad more load capacity and bring the ride height back up to factory specifications with the added weight of the larger engine. I found that the 2600 motor didn’t require these springs. However, when I replaced that engine about 15 years ago with a larger 2800 cc one, changes made to the block for strengthening reasons lead to a slightly heavier engine and the need for uprated front springs. I went to the larger engine mainly for parts availability as parts for the 2.6 liter became increasingly harder to come by, having only been imported for two years. The additional braking afforded from the GT6 front and rear components is also much appreciated. Just to round things out, the car is fitted with 6 inch Panasports and 205/60R BF Goodrich radial TA tires.

The exhaust is getting an improved muffler in the next few weeks, as the stock TR6 one fitted is a bit restrictive at higher RPMs. After much research, I opted for a Borla muffler, and I will be welding up the pipes as soon as I get everything ordered.

The car is painted in a 1988 GM/Chevy truck color, Bright Red Iridescent, which is a clearcoat/basecoat paint type (most commonly referred to as paint code number 9206 in Duplicolor’s line of paint). It received that paint back in 1988, as well as the GT6 bonnet, when somebody backed into the car while it was parked on the street.

This car is my daily driver, so a few modern features are also incorporated. The Sony Stereo/CD player is boosted with a 100 W power amp installed in the trunk area, and powers a ported sub-woofer system that fits over and completely covers the parcel shelf. If you were to look in the back you would see a slanted shelf that looks just like part of the car. You wouldn’t think twice about it and would just think that it was the rear panel unless you were to look at it more closely and noticed the cutouts under the grill cloth for the sub-woofer and twin drivers that are mounted there. Cruise control is also fitted, which is a real blessing on long trips. The dash is made from ABS plastic that I machined and fitted with TR6 gauges for oil pressure, amps, fuel level, and water temp, as well as large rocker switches for the wipers, lights, and the two speed heater motor.

This project is still evolving, but at this stage, after twenty some years of changes, I think I have modified almost everything that I’ve wanted to modify. It’s more fun than any car I have ever owned. It handles beautifully, has plenty of power, more than you really need, and is as reliable as any modern day vehicle. But who knows, you know that 4.0 liter Ford Explorer is basically the same block. . . and with just a little more fabrication… Honey, do you think…